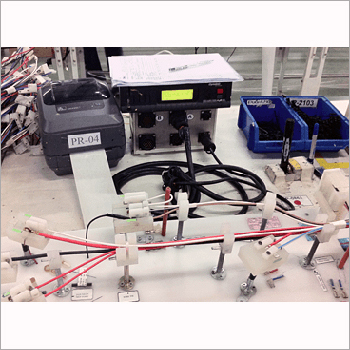

Wire Harness Continuity Testing Fixture

MOQ : 1 Pack

Wire Harness Continuity Testing Fixture Specification

- Max Height

- 120 mm

- Automation Grade

- Semi-automatic

- Operating Voltage

- 24V DC (internal logic circuits)

- Mounting Type

- Tabletop

- Specimen Size

- Custom configurable

- Equipment Type

- Wire Harness Continuity Testing Fixture

- Temperature

- 5C - 40C

- Resolution

- 0.01 ohm

- Response Time

- <2 s

- Display Type

- Digital LED display

- Accuracy

- 0.1%

- Features

- Audible alarm, LED status indication, data logging capability

- Port Size

- Standard terminal block ports

- Humidity

- 20% - 85% RH

- Test Range

- 0-1000 wires

- Interface Type

- USB & RS232

- Frequency

- 50 Hz

- Number of Specimens

- Up to 10 at a time

- Power Supply

- 220V AC, 50 Hz

- Measuring Range

- Continuity and open/short detection

- Usage

- Wire continuity testing

- Capacity

- Multiple wire configurations

- Machine Weight

- Approx. 12 kg

- Test Speed

- Manual & Automated options

- Test Width

- Up to 200 mm

- Test Stroke

- Up to 250 mm

- Control Mode

- Microcontroller based

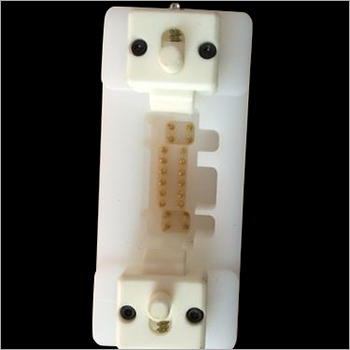

- Probe Type

- Spring-loaded contact

- Test Method

- Contact resistance measurement

- Fixture Material

- Aluminium & ABS

- Fault Indication

- Buzzer & LED light

- Compliance

- CE & ISO 9001

- Protection

- Fuse protected circuit

- Storage Temperature

- -10°C to 60°C

- Cable Length Supported

- Up to 2.5 meters

- Multi-channel Testing

- Supported

- Data Output

- Printable report via USB

Wire Harness Continuity Testing Fixture Trade Information

- Minimum Order Quantity

- 1 Pack

- Delivery Time

- 1-7 Days

- Packaging Details

- carton boxes

- Main Domestic Market

- All India

About Wire Harness Continuity Testing Fixture

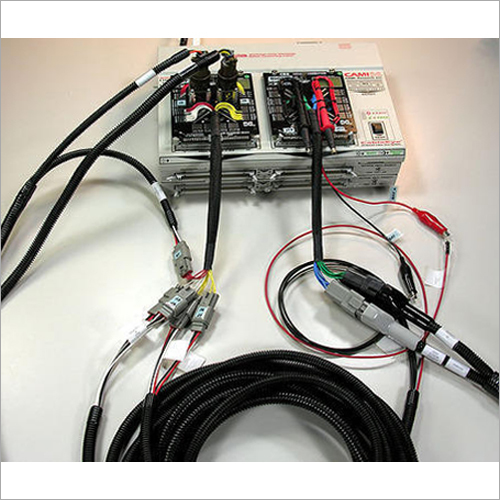

Get the best price for a matchless Wire Harness Continuity Testing Fixtureoffered at an unbeatable deal for a limited time! Engineered for potent performance and top-notch reliability, this fixture enables seamless multi-channel testing up to 1,000 wires with a digital LED display. The spring-loaded probe ensures accurate contact resistance measurement, while LED and audible fault indication guarantee swift diagnosis. CE & ISO 9001 compliant, its fuse-protected aluminium and ABS construction ensures durability. Enjoy automated or manual testing and printable USB reports. Ideal for the automobile industry, powered by 220V AC, and featuring microcontroller-based control for optimum precision.

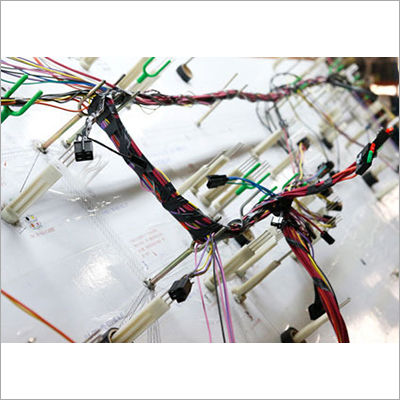

Key Applications for Wire Harness Continuity Testing Fixture

Widely utilized in the automobile industry, the Wire Harness Continuity Testing Fixture facilitates comprehensive wire continuity testing across multiple configurations. Its robust design also suits applications in machinery, electrical panels, and custom wire assemblies. The fixture is invaluable for production lines where detection of open/short circuits is essential, ensuring reliable harness functionality at every stage.

Payment, Delivery, and Domestic Market Details

Expenditure for this superior fixture is transparent and competitive, perfect for manufacturer export markets and Indian suppliers. Quick delivery times ensure expedited handover, minimizing production delays. We accommodate flexible payment terms to suit your organizations needs, with strong coverage across Indias main domestic marketensuring your procurement process is seamless from order to installation.

Key Applications for Wire Harness Continuity Testing Fixture

Widely utilized in the automobile industry, the Wire Harness Continuity Testing Fixture facilitates comprehensive wire continuity testing across multiple configurations. Its robust design also suits applications in machinery, electrical panels, and custom wire assemblies. The fixture is invaluable for production lines where detection of open/short circuits is essential, ensuring reliable harness functionality at every stage.

Payment, Delivery, and Domestic Market Details

Expenditure for this superior fixture is transparent and competitive, perfect for manufacturer export markets and Indian suppliers. Quick delivery times ensure expedited handover, minimizing production delays. We accommodate flexible payment terms to suit your organizations needs, with strong coverage across Indias main domestic marketensuring your procurement process is seamless from order to installation.

FAQs of Wire Harness Continuity Testing Fixture:

Q: How does the Wire Harness Continuity Testing Fixture detect faults?

A: It employs spring-loaded probes and measures contact resistance. Faults are indicated via LED lights and an audible buzzer for immediate identification.Q: What is the primary usage of this fixture?

A: It is mainly used for wire continuity testing in the automobile industry, detecting continuity, open, or short circuits in harnesses.Q: When can I expect the delivery after placing my order?

A: Delivery times are prompt and depend on your location in India, with a focus on rapid handover to minimize any operational downtime.Q: Where can the Wire Harness Continuity Testing Fixture be applied?

A: Its application spans automobile manufacturing, electrical panel testing, and custom wire assembly verification in production or testing environments.Q: What is the process for obtaining a printable report from the fixture?

A: Upon testing, results are logged and exported via USB, allowing you to generate a printable continuity report efficiently.Q: What are the main benefits of using this Wire Harness Continuity Testing Fixture?

A: Users gain top-notch accuracy, multi-channel testing, rapid fault indication, and matchless automation options, all while enjoying reliable data logging and CE & ISO compliance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Harness Tester Category

Wire Harness Tester

Minimum Order Quantity : 2 Pieces

Application : Automobile industry

Material : MS

Power Supply : Electric

Continuity Testing Fixture

Minimum Order Quantity : 1 , , Pack

Application : Automobile industry

Material : Other

Wiring Harness Assembly Fixture

Minimum Order Quantity : 1 Pack

Application : Automobile industry

Power Supply : Electric

Wiring Harness Terminal Backout Testing Fixture

Minimum Order Quantity : 1 Pack

Application : Automobile industry

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS